I had 14 panels to cut out. Some of these needed to be traced from the patterns, others needed to be made up from dimension drawings in the plan book.

This picture is about half-way through the tracing:

Most everything went pretty smooth but due to the large number of parts it did take me close to eight hours in the garage tracing, cutting, and cleaning up the mess (oh poor me :). Here's a picture of the resulting pile of panels:

Most everything went pretty smooth but due to the large number of parts it did take me close to eight hours in the garage tracing, cutting, and cleaning up the mess (oh poor me :). Here's a picture of the resulting pile of panels:

(The wood thing leaning against the door is my daggerboard case mold, with the rope channel mold in front of it.)

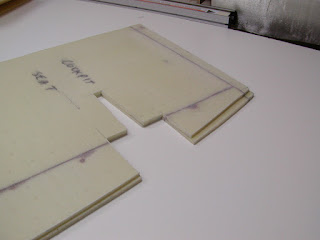

(The wood thing leaning against the door is my daggerboard case mold, with the rope channel mold in front of it.)Unfortunately, I did have one screw-up. The cockpit seat panel is a bit interesting. It does not have a pattern, instead you transfer measurements from the plan book, and you need to be careful with this one because the plan book draws the cockpit seat for all models (aft-cockpit + aft-cabin + cuddy-cabin) in one drawing with (mostly) a combined set of dimension marks. The aft-cabin version is the smallest of the three, and it requires doing some minor calculations to compute a couple of dimensions. I must have mis-read the measurements on one of the panels, because this is obviously not right:

The bottom panel has the correct dimensions. Not sure yet if I will try to fix this, or just bag up another panel. I was happy with how close the aft beam mount notch came out on both panels though -- not bad for doing a manual transfer of the dimensions plus jigsaw cutting.

The bottom panel has the correct dimensions. Not sure yet if I will try to fix this, or just bag up another panel. I was happy with how close the aft beam mount notch came out on both panels though -- not bad for doing a manual transfer of the dimensions plus jigsaw cutting.

Here is a shot of the mess I made:

I am nearing the end of my flat panel bagging work. Only panels left to do are the front beam bulkhead (2 halves) and the forward bunk top (2 halves), plus fixing or re-doing the cockpit panel. The fwd bunk tops will not fit on my vacuum table board, so they'll be done via open-layup. Another task I need to catch up on is filling in the exposed bulkhead foam edges with putty (already done for those float bulkheads that needed it).

I also spent some time figuring out my strategy for the float decks. At first I was going to do them in one piece, but changed my mind. I'm doing the decks in two pieces, one will be the forward 2/3 of the deck, and the other the aft 1/3. Yesterday I glued together the foam for making the forward deck pieces but didn't get around to doing anything else. I will doing an open hand-layup on these parts due to the length.

No comments:

Post a Comment