Last night I put an extra sealing coat of epoxy on the plywood inserts to prepare for laminating. While waiting for the sun to warm things up...

(go sun go!)

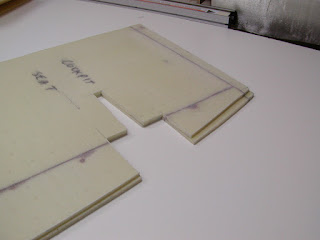

(go sun go!)...I worked on getting the deck stringers all cut up, mitered, and smoothed over:

(My numbering scheme for the stringers was 1 through 5, starting with 1 for the forward-most stringer. In case you're wondering later when you see numbers in the pictures.)

Per the plans, the underside laminate is not supposed to go all the way to the edge as this might create a hard edge during fairing. To accomplish this, I was able to use a trick I had read about in the System Three Epoxy Book guide (this method might be old hat to others, but it was the first time I've actually had an opportunity to use it), namely I put a strip of 3/4" masking tape all around the perimeter of the decks:

In the above picture, you can also see where I've pre-marked the stringer locations. The rough-drawn circles are for the screw-in hatches, but were for reference only -- those won't get cut-out and installed until much later.

In the above picture, you can also see where I've pre-marked the stringer locations. The rough-drawn circles are for the screw-in hatches, but were for reference only -- those won't get cut-out and installed until much later.

Then I cut up all of my fiberglass, including extra reinforcements, and layed it out on the decks: With the temperature nudging 55degF, and the skies blue, I decided it was warm enough to go for it. On to the laminating:

With the temperature nudging 55degF, and the skies blue, I decided it was warm enough to go for it. On to the laminating:

This was my first "large-scale" open-layup laminating effort on this project. I was happy with how smooth it went. I did learn to be frugal with the resin, since you don't want to have to sop up any extra, and the resin will usually go further than you think it will (just have to be patient as it soaks in). On these float decks, it was easy to handle any excess, of course: just squeegee it over to the next section. Eventually I got done with laminating both decks, including reinforcements.

Next I mixed up a batch of putty and glued all of the stringers into their pre-drawn locations. In some cases I didn't get quite enough squeeze-out, and had to go back with extra putty to form small fillets around the base of each stringer. I then wet out the stringer reinforcements one by one in the garage, carried them out to the boat tent, and laid them into position. I didn't want to try to wet these out directly in place on the float deck, and the pre-wetting method worked awesome. However, even with the mitered edges and my extra sanding to smooth the corners over, I still had a tiny bit of trouble getting the cloth to lay smooth around some of the corners -- it kept wanting to bubble up. In the end, I just kept checking these over and over the rest of the day, fixing them as needed until the epoxy started to grip the cloth more firmly. Here's how they looked when done: At this point, I went and took a break to allow the epoxy time to cure. I needed to remove the masking tape before things got too sticky, but things weren't curing quite fast enough (remember I'm using slow hardener). I ended up taking my heat gun and going around the deck perimeters a couple times to speed up the cure next to the masking tape. Then it was time to cut a line next to the tape, and lift off the tape and (cut-off) laminate as one piece. This worked well and I was very pleased with the edge it left:

At this point, I went and took a break to allow the epoxy time to cure. I needed to remove the masking tape before things got too sticky, but things weren't curing quite fast enough (remember I'm using slow hardener). I ended up taking my heat gun and going around the deck perimeters a couple times to speed up the cure next to the masking tape. Then it was time to cut a line next to the tape, and lift off the tape and (cut-off) laminate as one piece. This worked well and I was very pleased with the edge it left:

After doing this for both decks, and pressing down any lifted cloth (only in a couple of spots), I was done:

After doing this for both decks, and pressing down any lifted cloth (only in a couple of spots), I was done:

(The plans call for some extra fiberglass reinforcements on the top of the decks, but I think I am going to just store them away for now and do it later after installing the decks.)

(The plans call for some extra fiberglass reinforcements on the top of the decks, but I think I am going to just store them away for now and do it later after installing the decks.)

All in all it was a good day and the results looked outstanding -- I am happy. :)